Universal Line

Consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Explore the Jensen Line

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante.

Over the years, we have pioneered a unique hybrid approach that seamlessly blends the strategic rigor of a consultancy, the creative innovation of an agency, and the mission-driven principles of a non-profit. This integrated model enables us to develop holistic, high-impact solutions that catalyze transformative change across sectors and geographies.

Jane Doe, production manager at Large Spanish chocolate company

Two stand-alone lines for simpler moulding applications with an open layout that facilitates the overview of the production

Two stand-alone lines for simpler moulding applications with an open layout that facilitates the overview of the production

Solid moulding, One-shot moulding and FrozenCone® Shell

Increased output capacity with new 700×18″ moulds

For tablets, up to 2100kg/h and for pralines, up to 1800kg/h.

The Jensen Line has completely transformed our business and enabled us to run a much more efficient production at our new site.

Jane Doe, production manager at Large Spanish chocolate company

Specifications

| Type 500 x 9-16” | 10 moulds/min. – 480 kg/h 15 moulds/min. – 720 kg/h 20 moulds/min. – 960 kg/h Depositing area – 193,8-371,6 x 370 mm |

| Type 700 x 9-16” | 10 moulds/min. – 740 kg/h 15 moulds/min. – 1100 kg/h 20 moulds/min. – 1480 kg/h Depositing area – 193,8-371,6 x 570 mm |

| Type 1.000 x 9-16” | 10 moulds/min. – 1.100 kg/h 15 moulds/min. – 1.700 kg/h 20 moulds/min. – 2.880 kg/h Depositing area – 193,8-371,6 x 870 mm |

| Moulding of solid products | • With or without inclusions • Tablets • Couvertures • Combinations of two or more chocolate types |

| Moulding products with | • Wafer • Biscuit centres • Big inclusions • Bars |

| One-shot moulding | • Centre-filled articles |

| FrozenCone® | • Cold-pressed shells, tablets & eggs |

How Hval Sjokoladefabrikk grew their business faster with Jensen Line

Chocolates Valor choose Aasted because of trust, reliability and the Jensen Line

Print materials & documents

User-friendly interface

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante.

Optimise with Aasted Insights

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante.

Installation & getting started

Get started with minimal downtime

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

We always test the equipment before shipping it to you

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Integrate it into your existing line

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Come test it at our

test-center

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc eu sem eu urna imperdiet auctor eu ac ante.

Reach out to hear more about the Jensen Line

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Get contacted by Aasted and get a quote

Print materials & documents

SuperNova Orbit

- Advanced temperature control.

- Temper up to 2500 kg/h.

- Aeration down to 0.5-0.7 g/cm³.

StellaNova Temper

- Up to 40% shorter cooling time.

- Use up to 30% less energy.

- Up to 75% less chocolate waste.

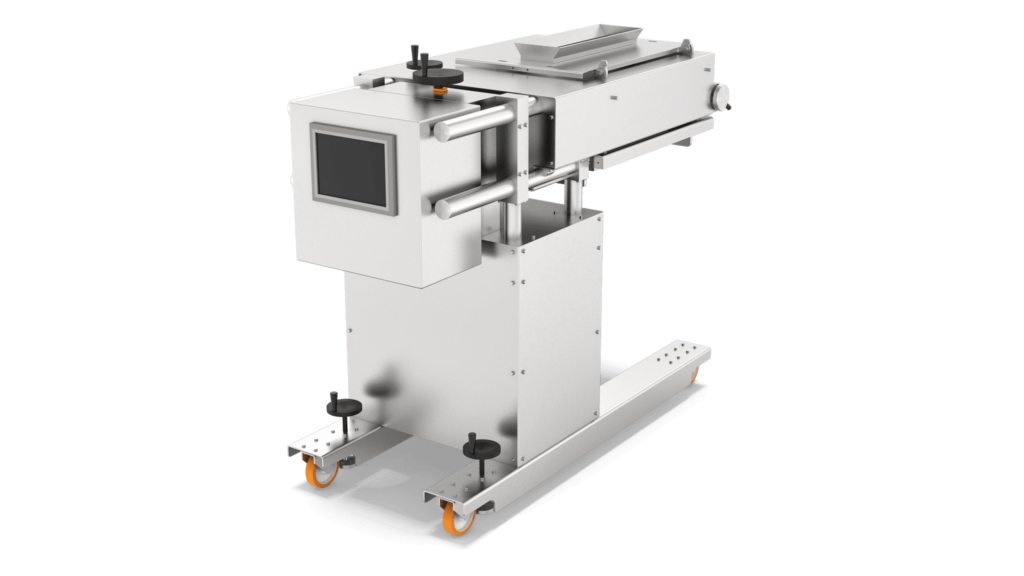

Bertha Stencil Depositor

- Width from 400-1200 mm.

- High precision and reliable forming.

- Allows for remote access.